Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)

ICP-OES

One of the primary applications of optical emission spectroscopy based on inductively coupled plasmas (ICP OES) is to analyze elements in very low concentrations. If considering metals such as mercury or metalloids like arsenic, then the reason for these analyses is not hard to understand. Soil sample investigations, foodstuff testing and drinking water analyses are all carried out for the health of people and the environment, but the environmental sector is just one of many important applications for ICP OES. Today, ICP OES plays a crucial role in other fields as well. Trace elements in fuels can cause premature wear on engines. The slightest impurities in metals can compromise the most important properties of those materials. Heavy metals contaminate drinking water for decades. High-frequency tests with low detection limits have therefore become the standard in many fields.

ICP OES takes on this role, superseding other methods of elemental analysis. Short analysis times, low sample preparation effort, multi-element detection and exceptional device sensitivity are hallmarks of this method. The latest generation of ICP OES devices makes elemental analysis even more user-friendly, economical, and flexible.

Description

ICP-OES

One of the primary applications of optical emission spectroscopy based on inductively coupled plasmas (ICP OES) is to analyze elements in very low concentrations. If considering metals such as mercury or metalloids like arsenic, then the reason for these analyses is not hard to understand. Soil sample investigations, foodstuff testing and drinking water analyses are all carried out for the health of people and the environment, but the environmental sector is just one of many important applications for ICP OES. Today, ICP OES plays a crucial role in other fields as well. Trace elements in fuels can cause premature wear on engines. The slightest impurities in metals can compromise the most important properties of those materials. Heavy metals contaminate drinking water for decades. High-frequency tests with low detection limits have therefore become the standard in many fields.

ICP OES takes on this role, superseding other methods of elemental analysis. Short analysis times, low sample preparation effort, multi-element detection and exceptional device sensitivity are hallmarks of this method. The latest generation of ICP OES devices makes elemental analysis even more user-friendly, economical, and flexible.

Atomic spectroscopy basics

Atoms absorb light of the same wavelengths that they themselves emit when luminescing. Because atoms can only absorb energy in specific quanta, the light they emit consists of different frequencies. Consequently, by looking at the spectrum of the absorbed or emitted light, it is possible to distinguish atoms clearly – two points of departure for elemental analysis.

Absorption or emission for atomic spectroscopy?

Although these theoretical fundamentals were discovered as early as the 19th century, they have only been employed in analysis since the middle of last century. It wasn’t until 1955 that the Australian Alan Walsh applied the theory of light absorption by atoms to chemical analysis. The idea: Atomic absorption spectroscopy (AAS), which entails measuring the concentration of elements in a sample by using light absorption. The first AAS devices hit the market about a decade after that. These atomize samples in a flame, known as the atomizer unit, in front of a light source of a specific wavelength. Measuring the intensity of the light before and after the atomization unit gives an absorption signal that provides information about the content of analytes in the sample.

Atomic emission spectroscopy (AES), more commonly known as optical emission spectroscopy (OES), takes the other route. It relies on the fact that excited atoms emit electromagnetic radiation. Based on the type of external energy input, OES with inductively coupled plasma (ICP OES) can be distinguished from other variants.

The principle of operation behind ICP OES

The essential characteristic is in the name itself: ICP OES uses an inductively coupled plasma to excite the atoms in the sample. A generator supplies argon gas with enough energy for it to jump to the next physical state. With a high particle density, the plasma reaches temperatures of 5,000 to 10,000 K. The measurement solution is then injected into the plasma. It takes a fraction of a second for the sample to dry out, melt and finally to vaporize. The gas molecules, which are now also being excited, are then atomized and ionized. They emit the electromagnetic radiation that is used for the actual analysis. Transfer optics direct the radiation to another optical component that can separate out the various wavelengths. After the waves are split, a detector registers the intensity of each wavelength, which is proportional to the concentration of the respective analyte. As the analysis depends on the correlation between the light intensity and the element concentration, calibration standards come into play. These calibration standards help to derive a mathematical function which relates radiation to concentration.

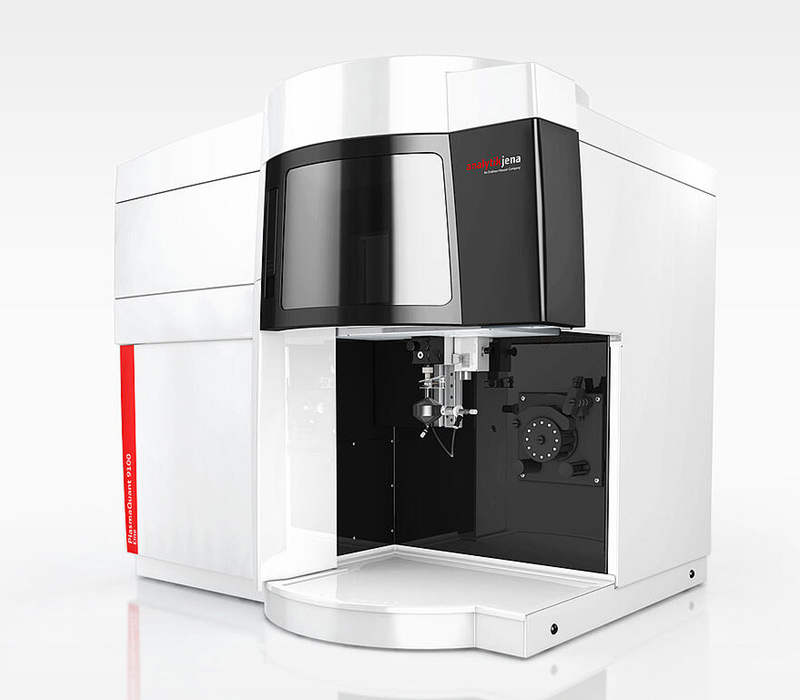

Structure of an ICP OES device

Generate the plasma, insert the sample to excite the atoms, then split and measure the resulting radiation: Those are the most important steps for ICP OES in a nutshell. The following overview translates these steps to the technical components of an ICP OES device.

- Plasma torch: This component is responsible for maintaining the plasma. The torch also has an injector which introduces the previously atomized sample into the plasma from the upstream sample insertion system.

- High-frequency generator: The plasma is coupled to a high-frequency generator responsible for feeding energy to the plasma. It operates at frequencies of 27 or 40 MHz, which are reserved internationally for this purpose.

- Sample insertion system: Many components come together here. A peristaltic pump delivers the measurement solution to the atomizer. There, a gas stream disintegrates the fluid into droplets. The downstream spray chamber serves to remove larger droplets from the resulting aerosol. The injector in the torch is connected to this component.

- Transfer optics: The transfer optics are not responsible for separating the wavelengths. They only serve to transmit the radiation to the dispersing optics.

- Monochromator/ polychromator: Separation into the component wavelengths can be accomplished in two ways: either sequentially (monochromator) or simultaneously (polychromator). With ICP OES it is critical that the optics can distinguish adjacent lines that are extremely close to each other.

- Detector: A CID or CCD sensor is used to detect the signals. The incident light on the sensor induces a change in charge which is processed as a signal.

Reviews

There are no reviews yet.